I’m doing some maintenance on our glaze kiln. The kiln is made by Kilns and furnaces and was bought by my mum sometime around 1975. We have fired it to 1260 degrees (cone 9-10) between 40 and 60 times a year since then. The cubic capacity of the kiln is 12 cubic foot. It can fire 161 mugs per firing. It has a serial number stamped on the door “02175” Here it is;  And with the door open:

And with the door open:  It is powered by calor gas. It has 4 venturi burners. Two on each side of the kiln. They look like this:

It is powered by calor gas. It has 4 venturi burners. Two on each side of the kiln. They look like this:  Here are the bag walls:

Here are the bag walls:  Okay. I’m going to start to take it to bits now and work out what i need to replace. Here is the kiln without the bag walls:

Okay. I’m going to start to take it to bits now and work out what i need to replace. Here is the kiln without the bag walls:  Here is the kiln without the bottom two kiln shelves:

Here is the kiln without the bottom two kiln shelves:  You can now start to see some of the problems. The 4 shelves in the middle are fine, but the 4 shelves on the outside are shot and need replacing. Here is a closer look:

You can now start to see some of the problems. The 4 shelves in the middle are fine, but the 4 shelves on the outside are shot and need replacing. Here is a closer look:  Here is one out of the kiln:

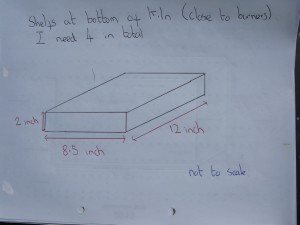

Here is one out of the kiln:  The dimensions of this shelf are; 2 inch thick and 8.5 inch by 12 inch. Here is a sketch of it with the dimensions;

The dimensions of this shelf are; 2 inch thick and 8.5 inch by 12 inch. Here is a sketch of it with the dimensions;

Taking the four shelves in the middle reveals this:  There are 4 AP2 bricks and two half AP2 bricks stood on end on either side which supported the 4 shelves. Here is a picture of one of these bricks close up. Note the proximity to the burners!;

There are 4 AP2 bricks and two half AP2 bricks stood on end on either side which supported the 4 shelves. Here is a picture of one of these bricks close up. Note the proximity to the burners!;  And here is one of the AP2 bricks out of the kiln;

And here is one of the AP2 bricks out of the kiln;  And a view of the other side:

And a view of the other side:  I need four of these AP2 bricks to replace the broken ones! Once these bricks are out it looks like this:

I need four of these AP2 bricks to replace the broken ones! Once these bricks are out it looks like this:  The two shelves underneath are fine. Here is what it looks like with these two shelves removed (I’ve also removed one of the burner deflection blocks on the front left):

The two shelves underneath are fine. Here is what it looks like with these two shelves removed (I’ve also removed one of the burner deflection blocks on the front left):  The brick work below these two shelves is fine. In fact the bricks look as though they were cut yesterday! Okay now onto the burner blocks; Three burner blocks look like this;

The brick work below these two shelves is fine. In fact the bricks look as though they were cut yesterday! Okay now onto the burner blocks; Three burner blocks look like this;  Which look fine. However one burner block looks like this:

Which look fine. However one burner block looks like this:  I wonder if this needs replacing? the discolouration might be due to a lack of oxygen from the venturi burner. In which case I should just need to open the venturi burner more and allow more oxygen into the kiln? The burner deflection blocks look like this:

I wonder if this needs replacing? the discolouration might be due to a lack of oxygen from the venturi burner. In which case I should just need to open the venturi burner more and allow more oxygen into the kiln? The burner deflection blocks look like this:  Here is one out of the kiln:

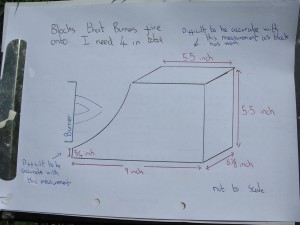

Here is one out of the kiln:  I cant decide whether to patch these up or get new ones? The block looks as though it is made out of cast-able refractory material. I guess I would have to make a wooden mould to make them? the dimensions are 9 inch by 6 1/8 inch base, 5.5 inch tall, 5.5 inch by 6 1/8 top, with curve. Here is a sketch of the block with the dimensions;

I cant decide whether to patch these up or get new ones? The block looks as though it is made out of cast-able refractory material. I guess I would have to make a wooden mould to make them? the dimensions are 9 inch by 6 1/8 inch base, 5.5 inch tall, 5.5 inch by 6 1/8 top, with curve. Here is a sketch of the block with the dimensions;

Here is a video of the 4 burners working;

Hope you have enjoyed this as much as me! If you have any opinions on the discoloured burner or on how to make the deflection blocks then please email me; lee@benthampottery.com

My friends and I at the pottery studio at Cary Arts Center NC, USA found this really interesting! Great pottery mystery. The home owner must be pretty chuffed to get central heating, a cellar and mystery a story to boot! is it possible the head was set in some table/counter top somehow which allowed them to grab the lead bard and spin it above the surface it was installed into?

Really glad you enjoyed it. I like your theory!